Just before dawn. A.C

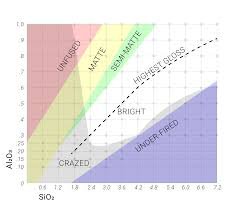

When I first started this journey I thought I Would finish within three months, I was wrong. Turns out I'm having to use everything I know including the new knowledge I find along the way. I recently learned how to make a good iron red. As a result I have made about three or four reds with my name on them. The main trouble with cracking the ancient copper code is that it’s a high alumina glaze with micro crystals. This is hard to achieve mainly because most crystal glazes are low in alumina, this is one of the reasons frit such as frit 3110 is used as a base for crystal glazes. The qualities being so far apart make it hard to decide where it goes on the stul chart ( a chart that helps us see where a glaze would land on the silica:alumina ratio when all ingredients and ratios are counted in). Here is a good example.

This is the stull chart

The left y axis denotes how much alumina

The right x axis denotes how much silica

When you put a recipe into a calculator this will map where you end up on this chart and give you a ration of how much alumina to silica your recipe has in it. This ratio is almost always ?:1 (the 1 being alumina)

For example 11:1 is 11 silica (really is groups of silica calles “moles” to every 1 alumina. Alumina is very hard to melt. It melts somewhere above 5,000f . So usually we have much more silica to alumina. The more silica in a glaze usually the more glossy is ends up being an visa versa.

This is a relatively matt glaze I developed. It falls under the part of the stull chart that is a little higher and to the left as that's where glazes are predicted to be matt and have less silica. This glaze only has about 8% silica.

But too much alumina makes it very hard to make these little micro crystals people like so much in a ancient copper glaze.

So here is what I have figured out so far.

The recipe has crystal…. of some sort…. Or an ingredient or combo of ingredients , enough to make crystals

Its matt glaze.

The Matt is not in in the part of the stull chart it usually is. I think the “matt” structure is due to the crystals forming a coat.

It very much needs either talc and bone ash ( I cant figure the ratio yet but it needs both)

It’s color is iron (best to have high purity iron)

Even though it’s a matt-ish glaze it still has movement.

Another part of my main issue, I cannot find a mineral with a good source of alumina past e.p.k . Or at least I do not know of one. Of course I was in the wrong part of the stull chart for about 4 months. For some reason I saw the crystals in the glaze and thought it was just a low iron crystal glaze. My next step, and this will be my final batch of tests before I give up, is a R.I.O vs Y.I.O test, a bone ash line test ( to see if the calcium is messing up the color), and a iron test. I think it’s between 10-14% iron. We should be able to close off this story with these tests. I knew from previous experience at a certain amount of calcium or bone Ash was required in the recipe to make good reds and from that point I just started dumping a bunch of bone Ash and stuff hoping for the best. I'm now finding out that there's a certain ratio of bone Ash that makes a good red and there's definitely a line that will turn the red into Brown. I'm sure there's an actual chemistry ratio to it that I could give if I did enough experimentation but for now it seems like 10-12% iron to about 8% bone Ash is The Sweet spot, depending on the other materials but that's a very general amount. This is probably going to be my next adventure as my last test which had far too much bone Ash in it turned out to be exactly what I wanted for ancient copper.

This is as close as I have gotten so far with a Matt Crystal glaze. The only thing I'm missing from this in order to make it ancient copper or at least be most of the way there is to make this brown actually be red. That's it, if this picture was in red we would be so close that we would only have to fine tune it. All of this is to show you that my most recent test got the proper texture and crystallization that I'm looking for. We're technically 2/3 of the way there.

This is the melt, texture, micro crystals, and movement I'm looking for in this glaze….. I just need it to be red.

Update: Looks like someone has had this venture before me. Also seems they put together a list of things they have found make a good red glaze in oxidation. A long article was written along with a summery.

Here is the article.

https://cone6pots.ning.com/forum/topics/iron-glazes-and-achieving-red-color-in-oxidation?commentId=2103784%3AComment%3A89945

Here is a excerpt from the article.

“The best iron reds in oxidation firing are obtained with about 0.10 molar CaO, 0.03-0.06 MgO, 0.01-0.02 P2O5 and 0.08-0.12 FeO”

The article states in order to get a good red color in oxidation you need a balance of phosphorus and calcium, between CaO, 0.03-0.06 and 0.01-0.02 P2O5 , Two things bone ash provides. So I was on the right track but I now see the footsteps on the beaten path. Getting good color vs getting a specific melt (matt or otherwise) in a glaze are two different things. It’s easy to get a specific melt or feel; matt, semi matt, glossy, all that is just silica and alumina ratios. But the color is a different story. Reds seem to be greatly effected by the calcium and phosphorus amounts…. at least thats what this article says….. here is why I hesitate.

I see plenty of examples where this is not true. Lets take these glazes for example.

Randy’s red original glaze recipe extended umf

DOSENT EVEN HAVE PHOSPHORUS IN IT! and it has 0.29 Ca0 in it which is waaaaaay over the CaO, 0.03-0.06 the article states. It is still a very popular red.

Tony Hansens red glaze cone 6 ox extended umf

Has 0.36 Calcium and .08 phosphorus. Again way over the amounts the article states.

I have created plenty of good reds that go way over the amounts stated in this article. But when presented with new info/ guidelines I usually want to test them out to see how they serve me. SO my next test will be with three different glazes all with lower amounts of calcium at cone 6 ox. as low as I can get them so we can be in line with the article. All red cone 6 ox glazes I have come across have been over 0.1 molar amounts of Ca0. Maybe they misplaced a decimal?

Next test decrease the amount of bone ash in reliably red glazes to see color change.